Are AI and automation the future of the offshore industry?

AI is implied throughout the news cycle to be coming for human jobs. With 50% of oil and gas executives saying they have already begun using AI to help solve challenges in their organisations, is it only a matter of time before the industry is 100% AI? Not necessarily. But, if it were, could this benefit the offshore industry AND its current organic workers? Let’s discuss.

Safety first

The system knows its faults.

Wind turbines face the elements 24/7. A sizable collection of problems can occur within them, and early recognition of issues can save time, money, and further damage. As examples of these errors, when the yaw is misaligned or the pitch bearing fails, failing to achieve the optimal output of the turbine is guaranteed. Integrating AI into the infrastructure of wind turbines can accurately predict when the yaw is off by even a single degree in a second. With machine learning incorporated into the mix, the prediction can arrive earlier and earlier as AI begins to spot patterns arising from the data it takes in, massively reducing wasted energy production potential.

The conventional way of testing the pitch bearing health involves stopping the turbine, entering the hub, and taking grease samples for analysis, the results of which can be subject to debate. AI can detect this issue remotely using existing sensors built into the turbine without additional hardware. Previous instances have demonstrated wind turbine failures reported with more than 90% efficiency up to 6 months in advance. The energy output that turbines can achieve with the automated system instead of the old human methods is far from negligible.

Disaster Recovery Plans

The ORCA Hub is one of the leading companies in advancing the development of AI and robotics to be integrated into the offshore industry. Part of their consortium is the Herriot-Watt University’s Smart Systems Group. Zero User Interface emergency plans and procedures are one of the group’s developed technologies. Integrating this technology into offshore projects means that in the event of a disaster on-site, there is an artificial helper a worker can shout to and explain where they are just on the observances they can make on their environment, such as signs and infrastructure. The AI can remotely take over all the levers and switches to contain the disaster and get workers to safety.

Practice makes perfect

Simulated major incidents can be programmed into the computer and rehearsed by workers in a safe environment, making workers better equipped to deal with a scenario like such should they arise.

The new integrated systems learn from the past data after being placed on an asset of a rig and analysing everyday functionality and dangerous situations. This analysis results in the AI-enhanced machinery that can predict accidents far earlier than the human eye could – nine days ahead of time compared to the previous hours if any time at all.

Let’s work together.

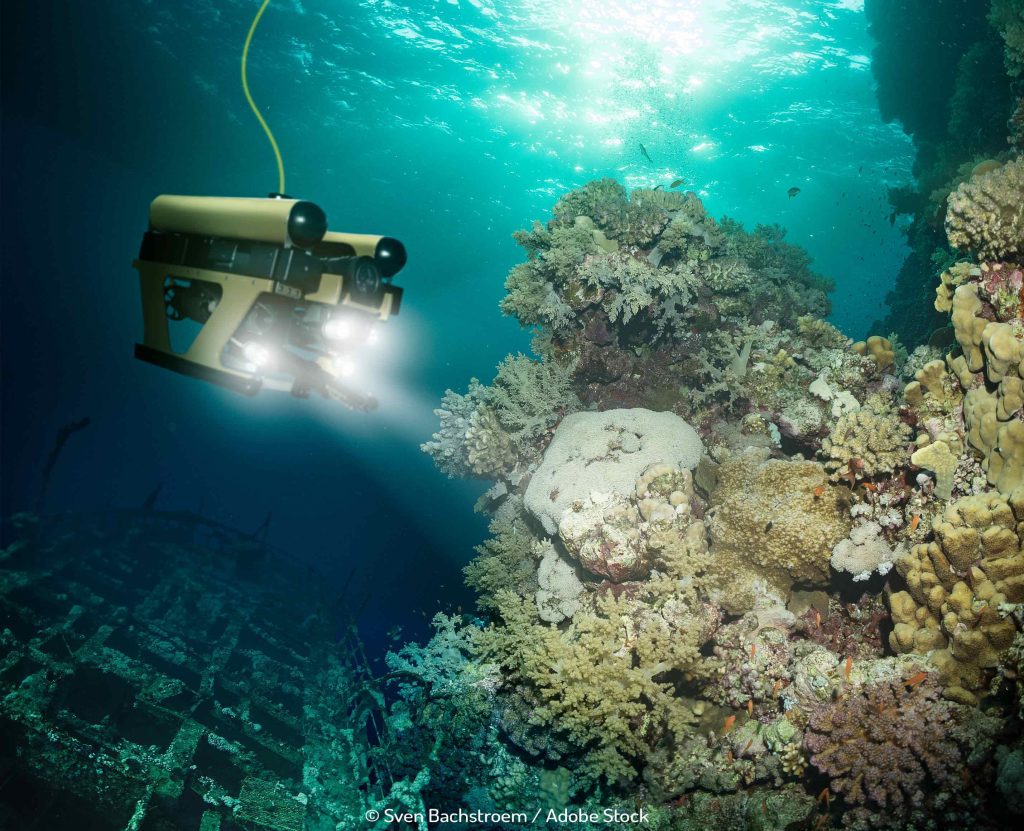

Another system in development by ORCA is MIRIAM (Multimodal Intelligent inteRactIon for Autonomous systeMs), a conversational integration of robotics and AI designed for work in hazardous areas. The focus point behind this technology is not just to limit human involvement in potentially life-threatening situations through autonomous ROVs but also a method of building human-machine trust. This software model can answer questions and explain its reasoning to human interrogators, as well as report on its health, making the interaction between operator and machine an increased two-way system and increasing understanding between both on the method of application.

But how can it improve the prospects of work stability for humans?

Finding the unfindable

During analysis, AI-integrated data processors can observe data shifts under the seabed that are invisible to the human eye. AI is so detailed focus that the enhanced system can calculate the change in recorded data into conclusions that humans couldn’t pick up on. These discoveries can generate scores of new projects for offshore workers by finding areas for extraction that wouldn’t have been possible without the help of AI.

Work from shore

AI presents a new situation in offshore work; thus far, most work on offshore projects is done on location offshore. When a worker is on a particular rig tending to their duties all the while, this becomes their life for the entire project duration. When part of the job is automated, and the location is no longer a tether, the opportunities for a worker to remotely perform duties on multiple projects open up, providing more avenues for positions than ever before.

New jobs

Three similarities we share with working robotics are the possibility of breaking, needing repair, and the need for management. For now, tending to these needs will require a mass of new humans filling the role of supervisors and maintainers for the machines and systems, particularly those with offshore expertise.

So, what could go wrong?

How much should we depend on AI to get it right?

AI makes decisions based on the data it has available. If an error infiltrates this data, the process will be wrong throughout. Without enough humans to notice the mistake promptly, the resolve will come too late.

Once a company fully integrates AI into its process, particularly something like an oil rig, to the point of mass automation, going back is complicated. The Covid-19 pandemic gave way to suspended offshore projects and a mass exodus of staffed workers. The aftermath of these events proves that if an automated system is insufficient, the previous human crew won’t be there on hand to return to their positions immediately. Replenishing a workforce like this takes time; in the energy market, time is money, and lots of it.

AI needs to know right from wrong.

It’s fundamental to understand that AI is not conscious, capable of spotting counterintuitive or dangerous patterns. It is a system trained on the day-to-day data of the systems it observes and replicates. To that end, a standard error made by some humans in a crew processed by the system could copy as a working method that continues. An error repeated so frequently could lead to consistent issues- the AI must train with the proper dataset followed to the letter for a decent period.

This possibility highlights that, currently, automation is capable of repetitive everyday tasks. Still, it needs to possess the creative problem-solving or judgement abilities of its human counterparts- this is something right now that can’t be artificially created and should spell longevity for the positions of offshore workers.